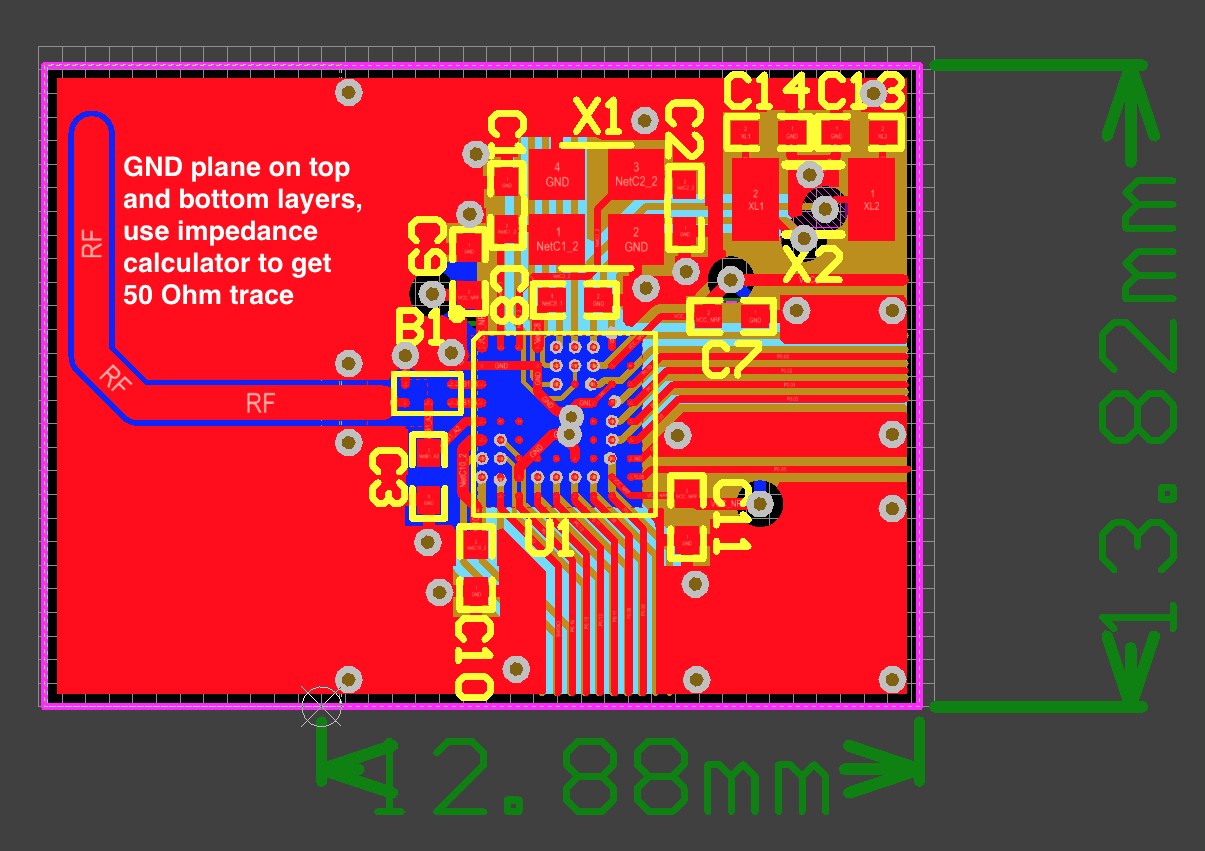

These planes provide a low-impedance path for the DC power currents, as well as a return-current path for single-ended signals. Multi-layer boards often have entire layers with solid copper planes dedicated to the distribution of power to the components on the board. Boards with dozens of layers are sometimes used to connect densely populated boards with high component pin counts. Four-layer boards are very common in low-cost products. These are referred to as multi-layer boards. Many boards have several layers of copper traces separated by layers of fiberglass epoxy (or a similar dielectric). Double-layer boards have traces on both sides. Single-layer boards have all the traces routed on one side of the board. Pin-in-hole components are held to the board by their pins, which extend through the board and are soldered to traces on the opposite side. Surface mount technology (SMT) components are glued to the top and/or bottom of a board. Circuit components with metal pins are connected by copper traces. Printed circuit boards like the one illustrated in Figure 1 can be found in nearly all electronic systems. However, the circuits that are often the center of an EMC engineer’s attention are those that are laid out on cardboard or fiberglass epoxy boards. Some circuit designs are fabricated on tiny silicon wafers and others consist of various components connected by cables.

0 kommentar(er)

0 kommentar(er)